Quality for over 75 years.

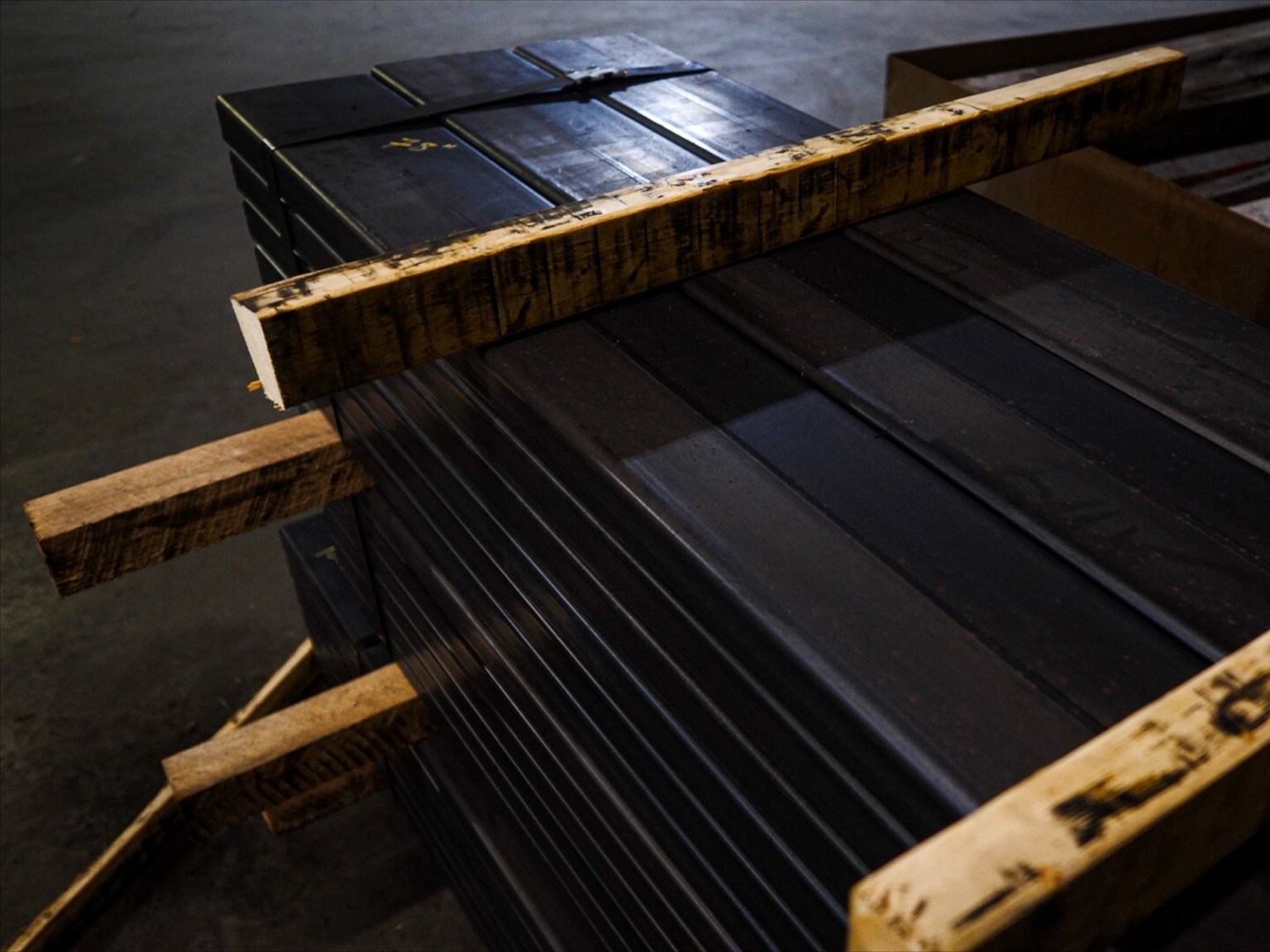

Since beginning operations in 1948 we have been stamping a variety of metals, Steel, Aluminum, Stainless Steel and Brass for diversified customer requirements. Areas of business include Automotive, Marine, Construction, Furniture, Interior Decorating, Recreational Vehicles, Garden Tractors and many others.

Products and services

-

Our Design and Engineering Support can assist in the resolution of problems ranging from Concept Development through Efficiency Enhancing Production Methods. Our Tool and Die Facilities allow us to build quality into our tooling and fixtures as well as assuring maintenance to satisfy customer specifications.

-

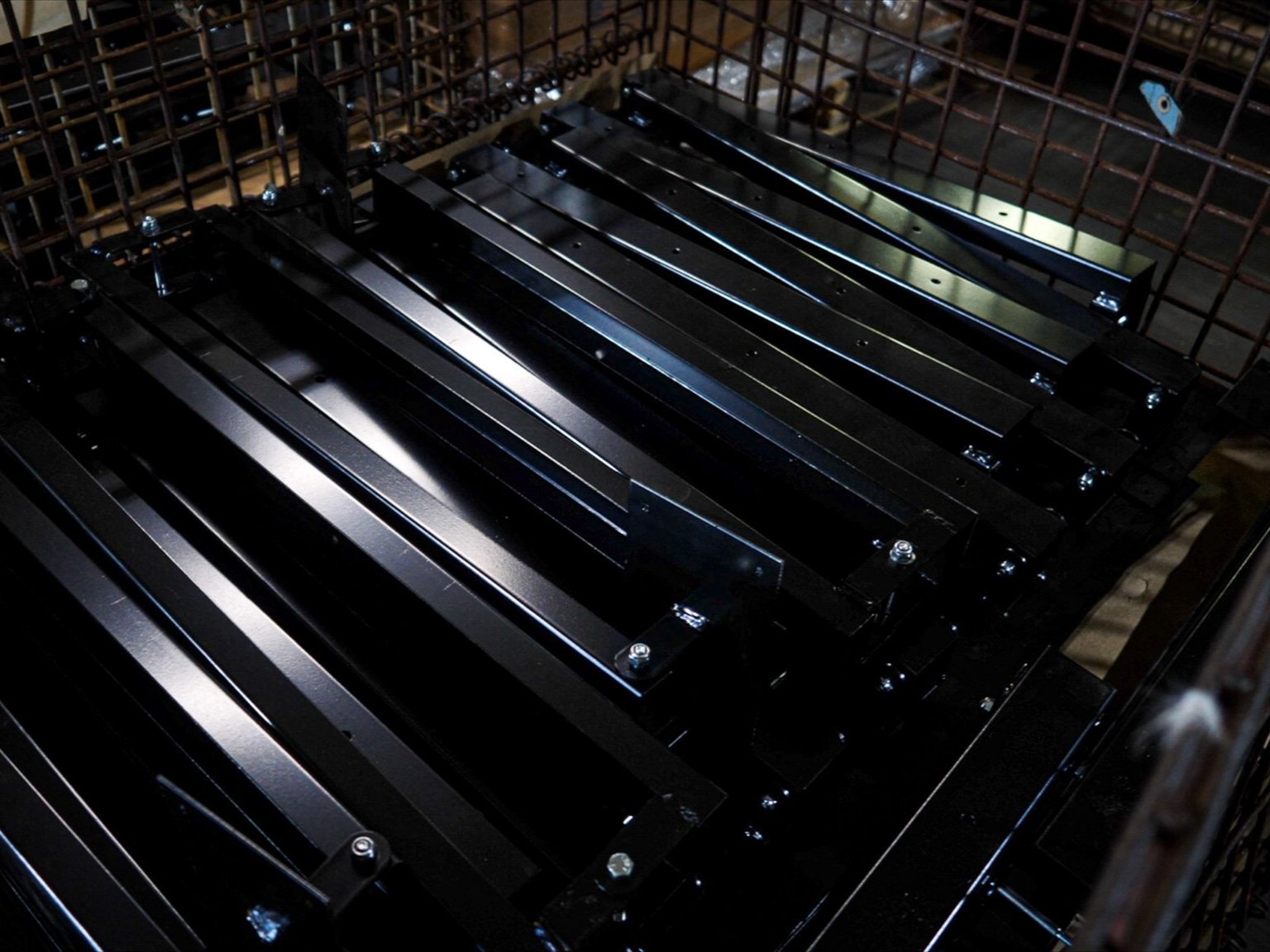

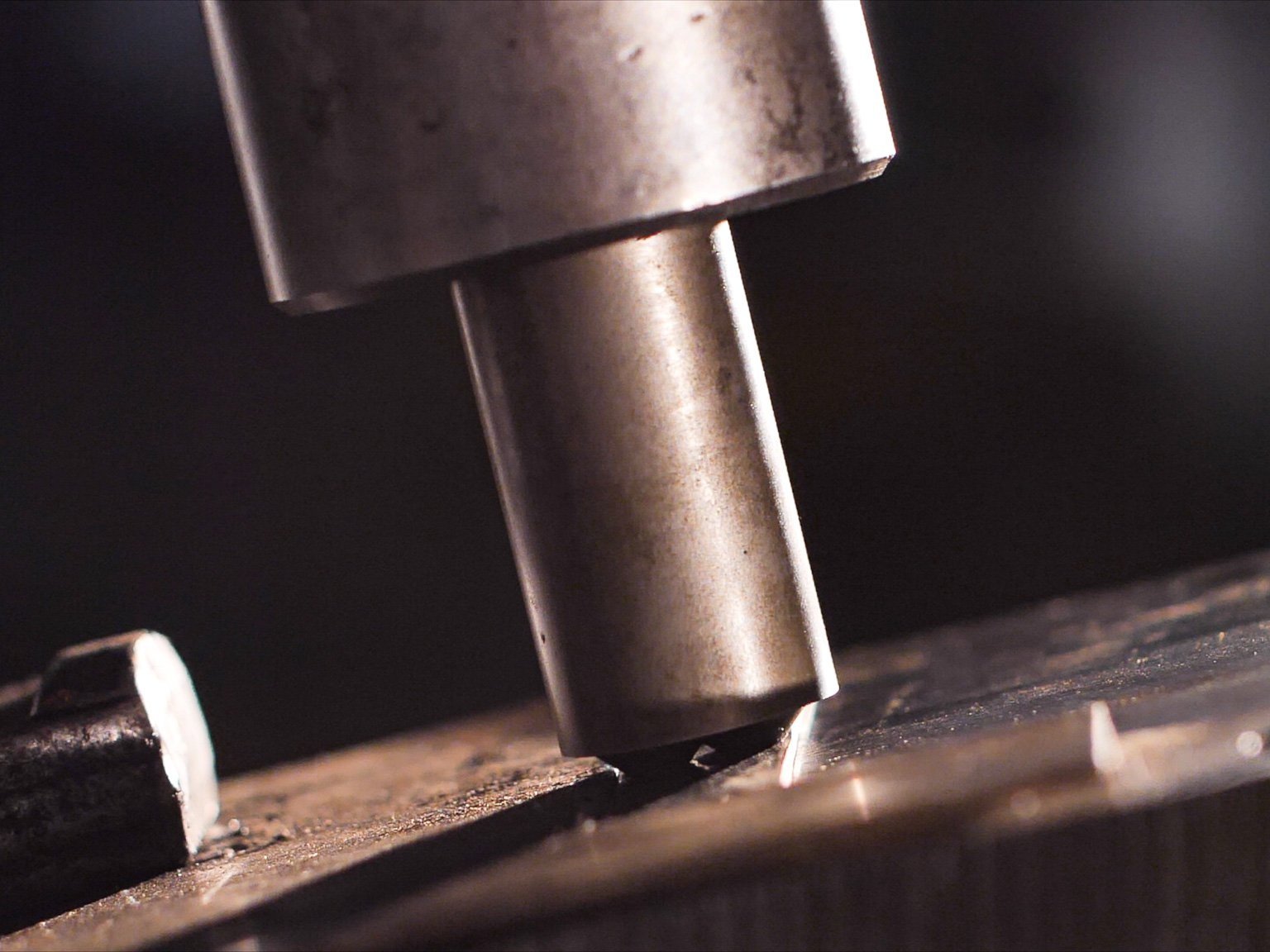

Blanking, Piercing, Forming, and drawing in materials up to 5/16" are some of the Stamping Processes we routinely handle in our over 100,000 sq. ft. of manufacturing facilities. Presses and Brakes up to 225 tons provide the flexibility required for short runs or long-term production on high-speed progressive dies.

-

Commitment to service is reflected through a variety of secondary operations available to you the customer. These services include: Riveting, Assembly Operations, In House Welding, Packaging, Heat Treating, Tapping, Shearing and Edging.

-

Gray Brothers is continually striving for quality improvement. We utilize various processes to achieve the goal. Checking fixtures for sampling and zero defects are designed and manufactured in our tool and die department. Company-sponsored in-plant quality training and computerized Statistical Process Control are used to satisfy even the most stringent customer specifications.